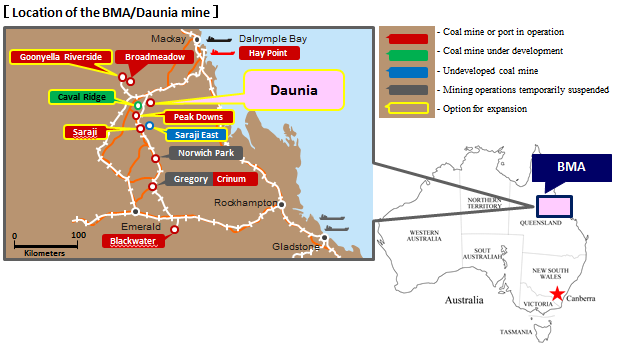

Daunia open cut coal mine is located in Queensland, Australia. The mine is owned by BHP Billiton Mitsubishi Alliance (BMA), a 50:50 joint venture of BHP Billiton and Mitsubishi.

The $1.4bn Daunia coal project included the development of a coal mine and a coal handling process unit, with a capacity of 4.5 million tonnes per annum (Mtpa) semi-hard coking coal and pulverised coal injection coal.

The mine commenced coal production in March 2013 and is expected to have a life of 21 years.

Daunia coal mine geology, mineralisation and reserves

The Daunia coal mine is located within the Bowen Basin, which is filled with fluvial and marine sediments. The Bowen basin is a part of Permo-Triassic Basin along with the Sydney and Gunnedah basins.

Coal deposits at Daunia are found in the Rangal Coal Measures and have a thickness of approximately 100m. Most of the coal is found in two coal seams – Leichhardt seam and Upper Vermont seams.

The coal found at Leichhardt seam is of five metres thickness, where as at the Upper Vermont seam it is three metres thick.

The Daunia coal mine has a metallurgical coal reserve base of 145Mt. The combined measured and indicated JORC-compliant metallurgical coal resources have been estimated at 157 million tonnes.

Mining and ore processing at BHP BMA’s Daunia

Mining activity at Daunia mine is primarily conducted at the Leichhardt and Upper Vermont seams. The truck and excavator method of mining is applied at the open cut mine. Coal from the pit is hauled to the surface using rear dump trucks and shifted to the processing plant by the mine haul road.

The coal handling and processing plant will handle 5.6Mtpa of Run-Of-Mine coal and produce 4.5Mtpa of coking coal. The CHPP includes a run-of-mine (ROM) dump station, coal receiving and sizing facility and tailings filter station.

The semi hard coking coal and the PCI coal are stacked separately on two stockpiles. Each stockpile has a capacity of 75,000t and consists of two separate product circuits.

The coal is taken to the Hay Point via the Red Mountain rail loop. It is then taken to the Dalrymple Bay coal terminals for export. The coal rejects and tailings are embedded within the in-pit spoil dumps.

Construction and infrastructure at Queensland’s Daunia mine

BMA started the construction activities at Daunia mine in 2011 and completed the same in July 2013. The mine development created 450 construction and 300 operation jobs. An overpass was built across the Norwich Park branch railway line.

Power supply for the mine and processing plant was provided by an extension to the 66kV overhead transmission line at the Millennium / Poitrel Project CHPP. The 66kV line originates from the Moranbah substation.

The infrastructure facilities, such as the road access and the water supply, were accessed from the neighbouring Poitrel and Millennium mines of BHP Billiton.

The construction works also included development of an additional train load out facility at the Red Mountain Rail Loop.

Employees are accommodated at the Mac accommodation village in Coppabella. The storage of diesel for the generators is provided on site in a 200,000 litre capacity tank.

Contractors involved with the Australian mine development

The engineering, procurement, construction and management services contract was awarded to Bechtel.

Golding was subcontracted for the construction works at the Daunia mine. The scope of the $163m worth contract included the development of bridges, culverts and bulk earthworks.

Downer Group was awarded the contract for conducting the mining operations at Daunia. Sedgman was awarded the contract for the construction of an 800t/h coal handling and processing plant at the Daunia mine.

Hatch was awarded the contract for providing the infrastructure facilities for the CHPP at the mine. The contractual scope also included construction of access and haul roads, power reticulation works, water supply and additional rail track.